Uploaded on 2016-09-01 by Sophia Mark

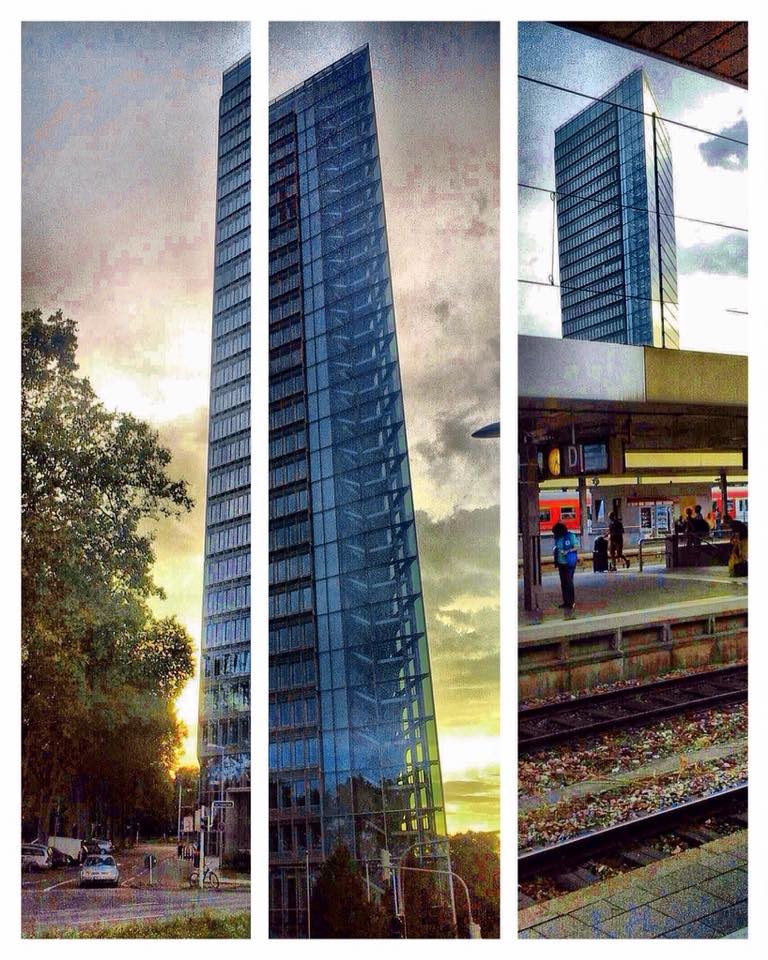

Viktoria Tower Mannheim Germany I found this building construction information in research in the internet. It is very interesting as glas is also a very new element which has changed the sight of global architecture in big cities in the last years. The Diamond (Viktoria Tower) in Mannheim as you can see in the picture is near the Central Station which I think also has a deeper meaning – of global connectivity. The choosen material -glas- as the material of future and also the higher menaing of the force in glas shows clearly that it is design out of itself. New urban buildings are built out of glas. Glas is transparent and in furture cities glas is a main element to make the invisible visible. The building itself is an expression and statement who is telling us a secret. This means for foreigners who change their train in mannheim central station can see the Tower. As there is no other tower or high building in the environment it looks very special and modern also mysterious. It was planned by the Frankfurt architectural office Albert Speer & Partner GmbH and opened in May 2001th The core of the building was created in 27 weeks. The area of each floor is 760 m². Outwardly the glass envelope and the shape of the Victoria Tower are striking. Its floor plan has the shape of a diamond. In the acute angles are staircases. It is equipped with 2 underground floors and 27 floors 97.5 meters high. It is a Bureaucomplex and its shape was made by the EUROGLAS plant in Osterweddingen which was completed in partnership with the Semcoglas group and glass Sprinz of 2006. At the sites Osterweddingen and Haldensleben produces EUROGLAS architectural and industrial glasses for European markets. This is very interesting about glas: The furnace is the heart of the production: Here the mixture of quartz sand, soda ash, dolomite and lime merges with the addition of sulfate as a refining agent for glass. Employed are about 2,000 tons of glass in the melting tank in which the required temperature of 1,600 degrees Celsius is maintained precisely by means of a natural gas fired around the clock. In a liquid tin the glass flows from the furnace and solidifies at a gradual cooling. It is then placed 3.21 meters or individual delivery measurements on tapes of 6 x, which is not cut in the strict sense, but only cut and controlled is broken. The glass thickness varies depending on the order from 2.6 to 12 millimeters. "Think global, act local": EUROGLAS products are sold all over Europe - but to invest in the future also means regionally to take responsibility. 530 people are employed at the two sites in Saxony-Anhalt. EUROGLAS committed to the health and education of its employees and trains. For better resource and environmental protection latest techniques are used in Haldensleben and Osterweddingen: An intelligent furnace design, air purification and heat recovery reduces energy consumption and pollutant emissions. CEO Christian Winter says: "In this way our glass contributes already during production to a sustainable and responsible value chain."